Today, robot arm machines are a building block of modern manufacturing and logistics in every industry. The precision, flexibility and automation capabilities make these advanced devices ideal for the reconfiguration of assembly lines. One such advancement is that of the robotic arm machine, which has done wonders to improve both efficiency and precision, thanks to its sheer versatility - we unpack their mechanisms further in this robot arms overview-how they help with automation better & faster yet eco-friendlier manufacturing by considering effective selection methods for a range of scenarios.

Well, to be honest this great thing called a robot arm machine has its own golden heart which is dexterous and consistent in the performance of repetitive tasks with top-notch precision at high velocity. This is because these machines do not get tired or make errors like human operators, and their only way to vary output quality is in a consistent fashion. It can run continuously for almost 24 hours, greatly reducing the production speed of interlocking and carving, but also with high precision! Using new-age sensors and control systems, they have better capabilities to sense in real-time so that the errors are reduced thereby reducing waste. A level of reliability required to change manufacturing processes into a high-efficiency configuration for improved cost control.

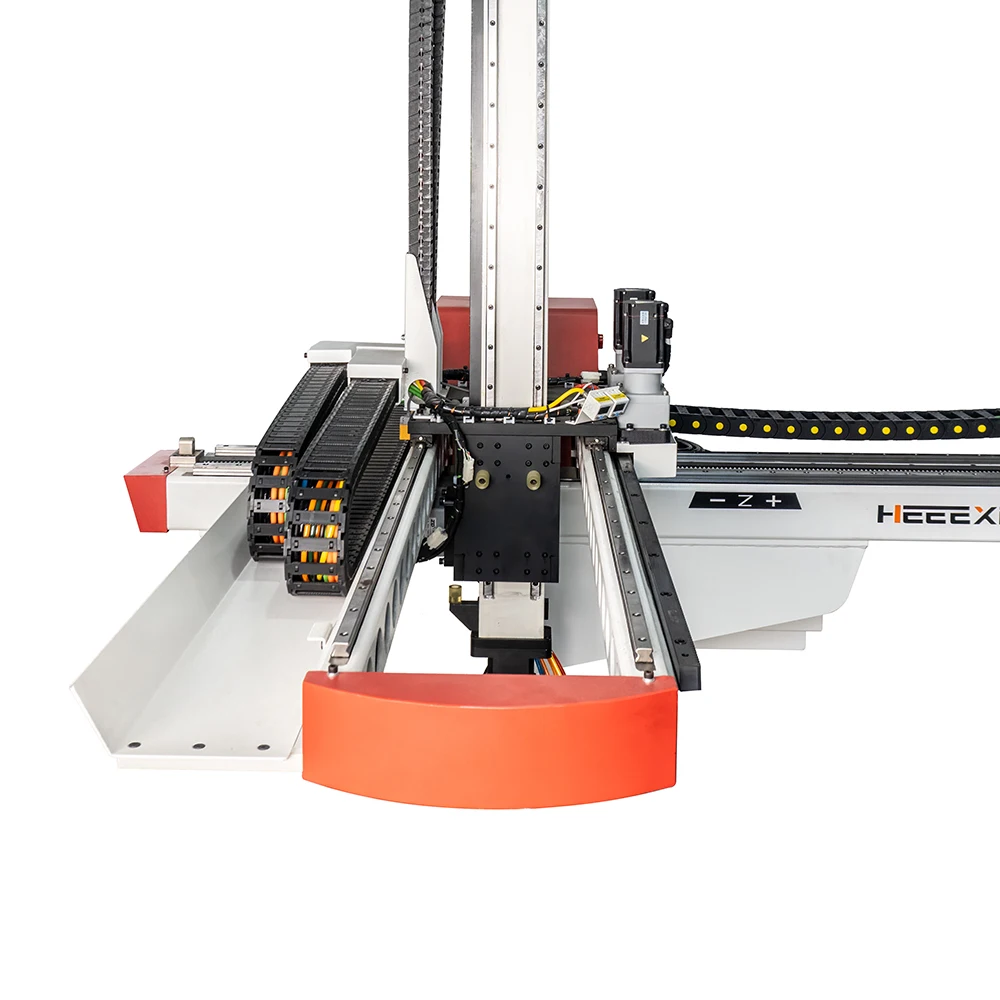

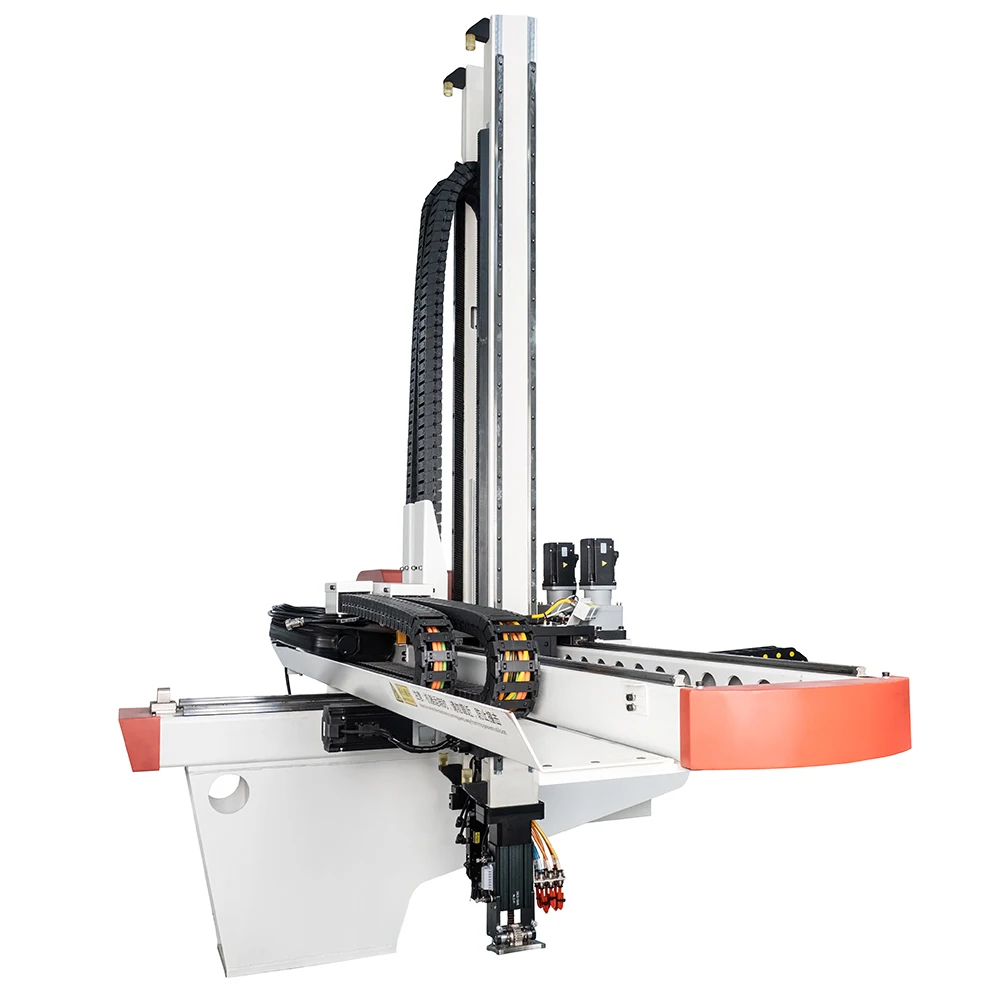

Perhaps the most fascinating part of robot arm machines is their vast flexibility. From performing fragile assembly tasks right down to the handling of heavier parts typical in automotive plants, these machines are configurable for any application. They are able to do many different tasks with interchangeable end-effectors, from simple gripping through welding or drilling; painting and inspecting even up to an automated productpicking. Furthermore, their capacity to move in more complex work settings and handle items with a high degree of precision & dexterity is advantageous if the industry demands very precise operations along with agility on the part of its workers. This adaptability leads to innovation and personalization that makes companies remain competitive in a volatile market environment.

Many features must be considered carefully when selection the right robot arm machine. Most important of which is its payload capacity i.e. it tells how much weight this arm can safely handle, The reach and range of movement determines the size are area which has access to by the arm. For tasks that demand levels of precision, both accuracy and repeatability are key. In particular, it is important to ensure that the machine control software can be integrated into existing systems and programs - for example with Industry 4.0 protocols.POWERLINK ensures seamless operation within your company's ecosystem; Evaluating maintenance requirements and cost of ownership throughout the life cycle will also help you to ascertain if it is a worthwhile investment in your operation.

The artificial intelligence (AI) that is integrated with robot arm machines brings automation to the next level. Artificial intelligence (AI) algorithms are embedded in these machines that allow them to learn from experience, adjust for changing conditions and even predict when maintenance is needed. Together, this intelligence helps them to make decisions based on their sensory input guidelines which help in optimizing workflows and responding to unexpected obstacles. Second, AI-driven vision systems increase the accuracy of factory robot arms since they can use visual clues to identify and handle objects as well alongside unstructured environments. As such these advancements are completely transforming the production scenario and it is leading to smart factories which certainly makes productions remarkably efficient.

We carry full servo 3 5 top entry robots axes 3 and 5 such sprue pickers, sprues, and 6-axis Fanuc. Our team design an entire robot arm machine cell that includes customized downstream equipment, as well as end of arm-tooling.

Heeexii's main values the pursuit of excellence as well as the desire be persistent. They also include creativity and a growing attitude excellence above oneself professionalism through determination, and the highest quality due professionalism. Heeexii Robot adheres to ideals of quality first and continual advancement. It offers solid reliable users while {{keyword} to China's smart manufacturing.

The products of company employed across a wide range industry, such as home robot arm machine, computer accessories optoelectronics packaging. Automotives and components, precision gears industry, PET preforms industry home essentials, mobile communications, medical supplies packaging industry.

Guangdong Heeexii Robot Technology Co. Ltd. was established in 2019 and a top-notch company that concentrates on R and D and manufacturing as well as sales robot arm machine robots. The company a staff of employees more than 10 years' experience in industry.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. All Rights Reserved