A robotic arm is the ruling machinery which performs intelligent and precision tasks at variable orientations being one of the effective technology ever made. These neat little gadgets are very clever in that they clean the functionality of an operation so standardization can be enforced. Robotic arms were everywhere-from garage manufacturing to medicals and even the outer space!

Robotic arms, for example can be incredibly useful in doing the same tick repeatedly with no issues. They have a high pin-point accuracy and can outperform tasks in environments that are dangerous to people. This way, people are spared from wasting their days in mundane tasks and spend more of what they want - productive activities by leaving those cumbersome chores upon the mercy of these robots.

The first amazing thing that robotic arms will accomplish, is make certain perfect execution of this tasks. In sectors such as the automotive and aeronautics it is a crucial function for robotic arm, in order to verify that everything meets very strict standards since these obviously have to be more accurate. They are also able to execute instantaneous quality checks for fast detection of errors, ensuring that they provide a high-quality product.

Apart from this Robots arm shows its immense versatility and adaptability makes it capable of simple or variety of applications. It does not require extra weight when using, but can be used in a variety of fields on the earth, including medical facilities and farms, as well as outside General robotic arms are so soft that they pull grapes from grapevines without tearing them apart.

Even less on-the-job specific are robotic arms, which can double as painters or chefs. Also, they help patients with physical therapy that lets their body become mobile again and can live on because there are many features in one.

Robotic arms, in its essence I awesome technology that combines the best of both humans and machines! Them are the vital assets for ease, quality and fun in a lot of sectors. As the technology of mechanical arms progresses, our role is bound to do so as well-ensuring both a future paved wide and full with possibility!

It is impossible to extricate the future of automation from this era of precision robotic arms. As you probably guessed, these systems are not only made to be executing certain repetitive tasks in perfect manner every time but for also learning from the experience and offering better experiences through machine-learning algorithms with performance optimizations. This ability allows them to adjust themselves according to the production lines, anticipate failure timings for maintenance action and keep on optimizing workflows dynamically. As Industry 4.0 rapidly unfolds, precision robotics will bring about intelligent factories from where devices communicate and decide in real-time to manage resources more effectively with minimal downtime. This enables an industry that is more sustainable, and resilient.

At the core of their allure, precision robotic arms refine an industrial process by minimizing errors and waste. This feature combined with their high accuracy and ability to work non-stop without getting tired ensures that the resultant output is produced flawlessly every time making sure there are fewer defects, improves throughput. They are adept at complex assembly procedures, for example, which include performing the most delicate handling tasks with a precision down to microns and working in hazardous environments where human workforce should not be sent. Consequently, when they are able to do these functions themselves, what effectively happens is that THAT frees up human resources so the humans can then get on with more creative types of thinking - you know deep problem-solvin tasks, in a safer and productive kind of way.

The direct product quality impact of blending robotics is one key advantage where precision robotic arms are concerned. Robotic arms are used in industries like automotive, aerospace and electronics where tolerances can be incredibly small - to help ensure that each component is assembled or processed with extremely accurate precision every time. This is important because we are talking about strict quality norms and compliance. These can also include sophisticated inspection technologies like vision systems which provide production-level quality control in real-time. Finding problems early on avoids the error class expanding and higher final product quality.

One of the most interesting things about precision robotic arms is how versatile they are. This has lead to more modern designs for systems with modularity making it easier such that these can be re-purposed and provisioned in different tasks and amended environments. Robotic arms serve a variety of purposes ranging from surgical suites, where they are used for delicate surgeries with the touch that no human has to work in food processing plants with hygiene as a topmost priority showcasing versatility. What is more, soft robotics are making massive leaps and bounds in flexibility or dexterity which means that robots could be better at handling items without any form of rigid packaging to hold them. This adaptability speaks to the broader opportunity for high-precision robotic arms which might challenge fields not just in conventional production however likewise health care, farming and even area exploration.

Heeexii Robot is characterized by the quest for excellence well as the determination keep going and innovation, a rising attitude and a desire to excel beyond oneself. professionalism due to focus; excellence due professionalism. Heeexii Robot will always adhere the {{keyword} of first-class quality control constant improvement, ensuring the stability and reliable of users as well as contributing China's intelligent manufacturing.

The products of company employed in many industries, including home appliances, computer accessories packaging optoelectronics, automobiles and their components Precision gears industry PET preforms industry, household essentials, mobile communication, medical supplies, precision robotic arm industry.

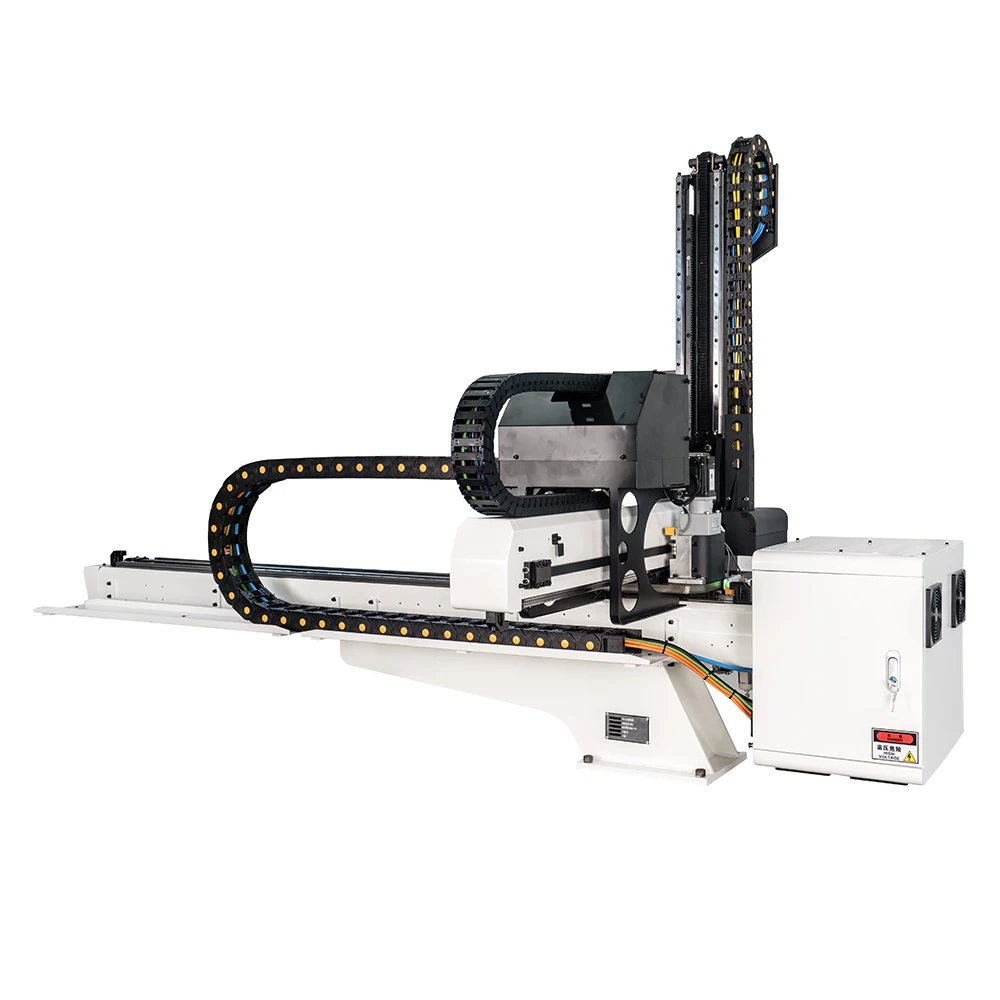

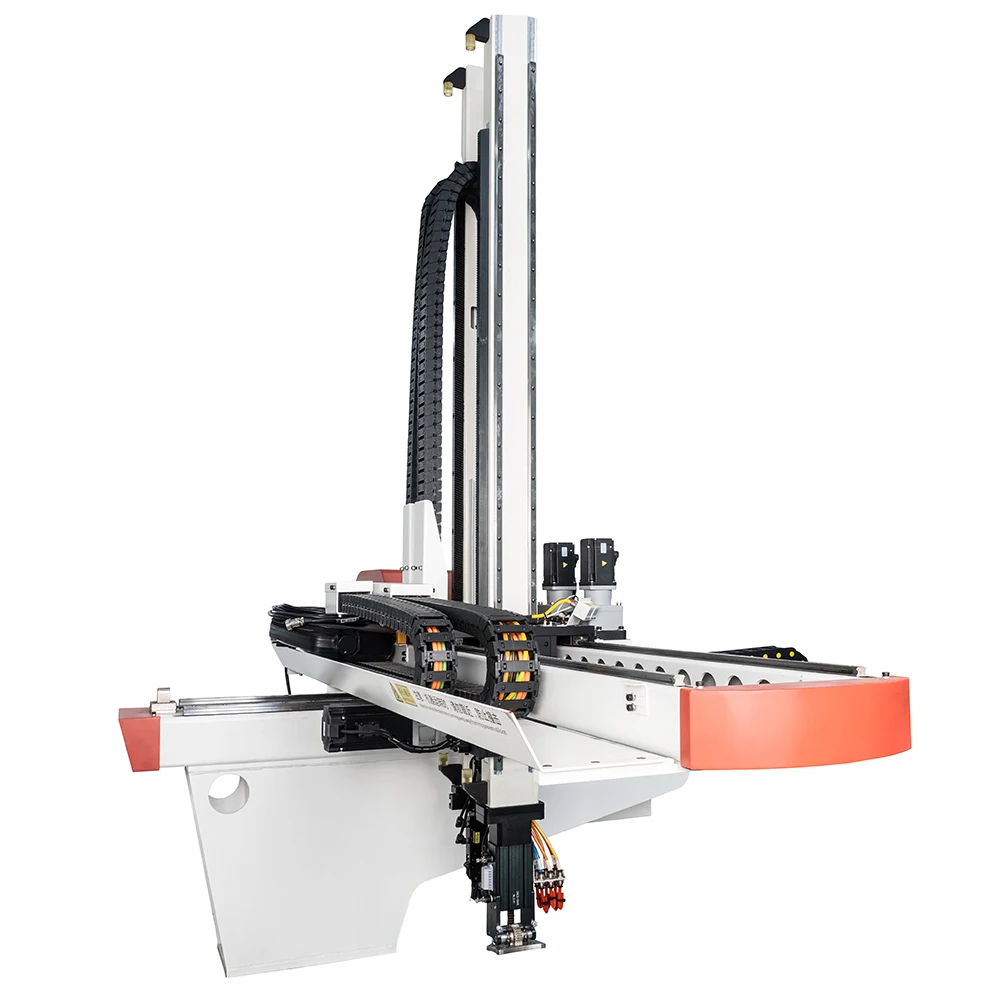

We stock full servo range of 3 and 5 axis top entry robots well as sprue pickers 6-axis Fanuc. Our precision robotic arm designs an entire automation cell includes customized downstream equipment, as well as the end of arm-tooling.

Guangdong Heeexii Robot Technology Co., Ltd. established the year 2019, is a new star enterprise focusing on R and D, manufacturing, and sales industrial injection molding robots. The company has dozens of employees ten years' experience in the precision robotic arm.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. All Rights Reserved