Get a Pro Bot Arm for your warehouse

Vintage manufacturing and logistics would have been quite a bit different had palletizing robot arms been available to help. These smart systems have changed the system of getting goods to be prepared for shipping and give a time-saving option that is still accurate. In order to maintain business competitiveness being pressured by heavy globalization lately, companies from various verticals are nowadays looking for palletizing robots as a reliable economical option.

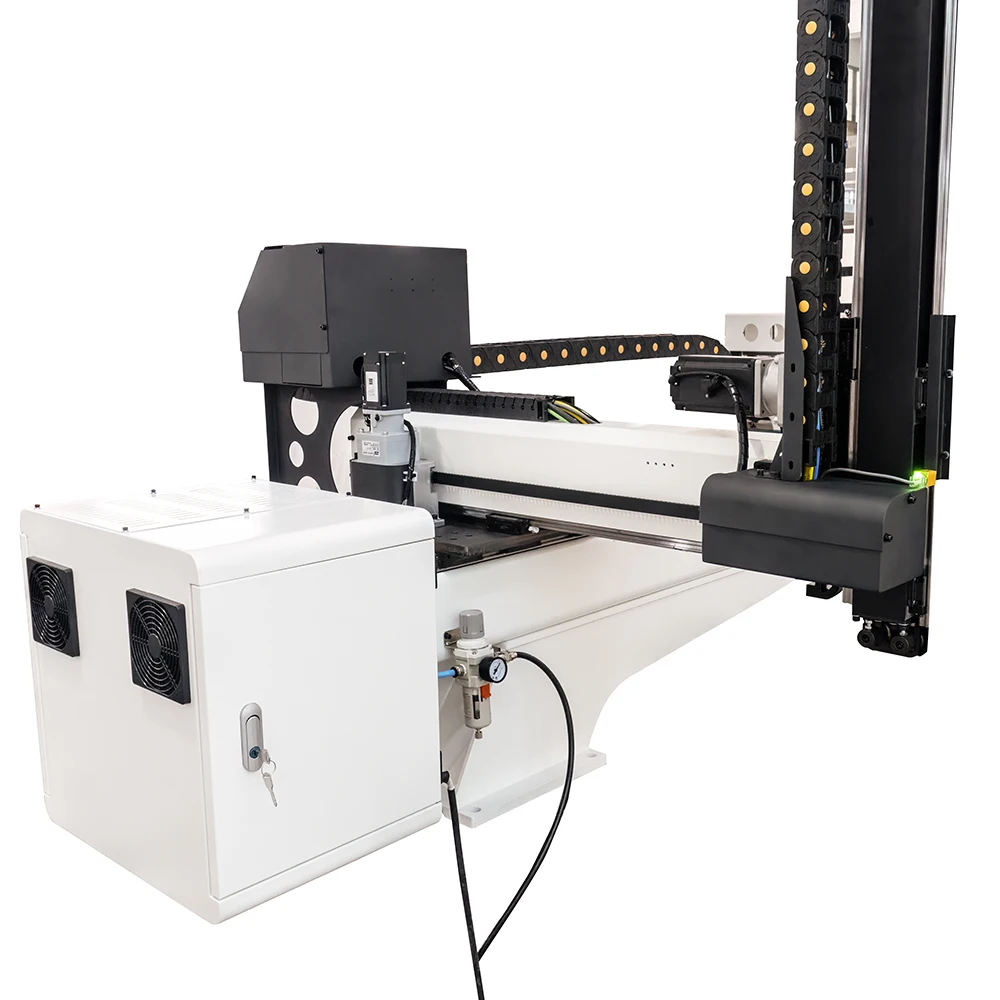

Warehouse operations efficiency relies on process optimization and performance maximizing. This philosophy is the basis behind large automatic palletizing robot arms, moving from a highly process-laden laborious effort of manually building up a pallet (which can be done in minutes by comparison) Programmable accuracy allows these future robotic systems to quickly adapt for different product sizes, shapes and stacking patterns. These allow the client to release their most intricate configurations quickly; which means faster cycle times per packaging and lower downtimes - Overall Warehouse Output sky rockets.

This eliminated the manual stage of stacking one by one and minimized human error. Robotic palletizers robots bring the packaging lines some points up but among them we know has integration in conveyors and wrappers, for example. The design of these bots is helped by some largest sensors that give the best computer vision capabilities and can detect, pick or place items much easier. Within this level of synchronization material is moving optimally and bottlenecks can be overcome to ensure that your permanent output maintains height. Moreover, by doing this they facilitate just-in-time (JIT) factory practices which might not only improve response and flexibility at a lower cost due to quicker adaptability of the method for new production schedules.

When the integration of palletizing robot automation provides some possible benefits in all-around processing, one of essential advantages is that you do not have to spend too much money on labor. Manual palletizing is notoriously slow and labor-intensive, leading to worker fatigue or injury. They can also choose to automate this particular task with machine learning and free up workforce for other high-skilled or decision making labour. Robots can also operate 24/7 (breaks and sick leave are a thing of the past) meaning cost savings never weaken with time. It enables the companies to achieve a better ROI and manage resource much efficiently which drives them towards sustainable growth.

These palletizing require a caution as any mistake can end to the damage in transport of product, reduction of customer satisfaction or risk for worker safety has caused. As illustrated here: a palletizing robotic arm armed with state-of-the-art algorithms and 3D vision systems, repeating predetermined patterns for uniform perpetuity across every single pallet load! Limiting factors that normally occur as a result of human processes can thus be dramatically reduced-imperfections in terms like skew and positive stacking capability are improved, helping keep final package integrity high while greatly minimizing returns/insurance claims (and the costs associated with managing those problems) resulting from sub-par applications on flexible packaging for brand- name product/items of cost or fragility.

Heeexii Robot is characterized by pursuit of excellence and perseverance; ingenuity, rising attitude desire to excel beyond oneself. professionalism because focus; and excellence due to professionalism. Heeexii Robot adheres o the philosophy of top quality and continuous improvement. It is a steady reliable user as well as contributing to China's intelligent {{keyword}.

We carry full servo range of 3 and 5 top entry robots axes 3 and 5, sprue pickers, and 6-axis Fanuc. Our team can create entire automation unit includes customized palletizing robot arm equipment, as well the end of arm-tooling.

Guangdong Heeexii Robot Technology Co., Ltd. established in the year 2019, is new star enterprise focuses on R and D, manufacturing and palletizing robot arm industrial injection molding robots. The company employs dozens of employees more than ten years expertise in the field.

The products of the company widely used industries such computers, home appliances optoelectronics cosmetic packaging cars and their parts metal processing equipment, precision equipment industry, PET preform industry, consumer electronics, mobile communication industry, medical supply palletizing robot arm packaging industry.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. All Rights Reserved