Over the years, industrial factories have significantly changed and now use robots as a part of their automation system. But the recent technological progress of jointed arm robot technology has raised this transformation to an entirely different platform. These incredible robots are designed to do a number of different things extremely well, and they may just change the way we manufacture products in the future.

The Jointed arm robot has several joints that duplicate the motions of our arms and can move in many directions. The reason why they are special is the advance software that run their operation - helping them perform tasks with precision and speed. Consequently, many companies are now looking towards these robots to provide a sure-fire way of boosting their manufacturing processes.

With this in mind, the expansion of jointed arm robots not only reduced and simplified steps to manufacturing but also sped up production processes - making it more efficient as well as less expensive. The robots have the flexibility to handle complex or delicate tasks within many sectors such as automotive, electronics and pharmaceutical.

Jointed arm robots are known for their extreme adaptability, which is one of the major advantages to using them. They can be built essaybot cost with the capability to partake in multiple tasks, from gripping of small parts to putting together large products. Businesses are able to use these robots for several purposes including welding, cutting, polishing and painting etc.

The latest arrival to the world of robotics is jointed arm robots are need of an hour and turning out as a game changer in various industrial applications. For example, in the automobile industry they have been instrumental on assembly lines performing a variety of tasks such as welding, painting and quality control to mention but a few.

These robots provide better precision and velocity than human workers, which, in turn increases the efficiency of cost-effectiveness as a rule. As a result, automotive businesses have saved much time and costs hence keeping up with the competition in the market.

Jointed arm robots can offer companies a major competitive edge. Built to be versatile, this type of robots can perform a wide range of tasks and represents an excellent choice for companies operating in diverse sectors.

Being available 24/7 means that they cater to large demands without compromising the desired level of quality. Even more, these robots eliminate risks of workplace accidents as they are able to work in hazardous environments such as those containing toxic substances or extreme temperatures.

Like any other innovation in technology, having a comprehensive awareness of the operations and ability concerning jointed arm robots are essential before procuring them. These robots may have different numbers of joints, payload capacities and size configurations.

The payload capacity indicates the maximum weight that a robot can carry and is something to keep in mind when determining what type of purpose the robot will be used for. Furthermore, the flexibility of applications affects its ability to perform various tasks depending on robot freedom of movement.

Additionally, jointed arm robots also carry end-effectors that are the specialized tools or devices which help them fulfil different responsibilities. End-effectors are the tools attached to robots grippers, suction cups, paint guns etc..

To take full advantage of articulated robots you will need a skilled operator to implement, operate and maintain. When programming the robot, you traditionally have to turn to using a special-purpose language tied directly with that particular model of your robotic kit.

In short, the future of industrial automation belongs to robots with articulated arms that provide businesses with flexibility in building automated process at an affordable cost. They are fast, accurate and multifunctional which has the power to act as a revolutionizer for businesses - A sure shot weapon with infinite capability in making any business far ahead of their competitors.

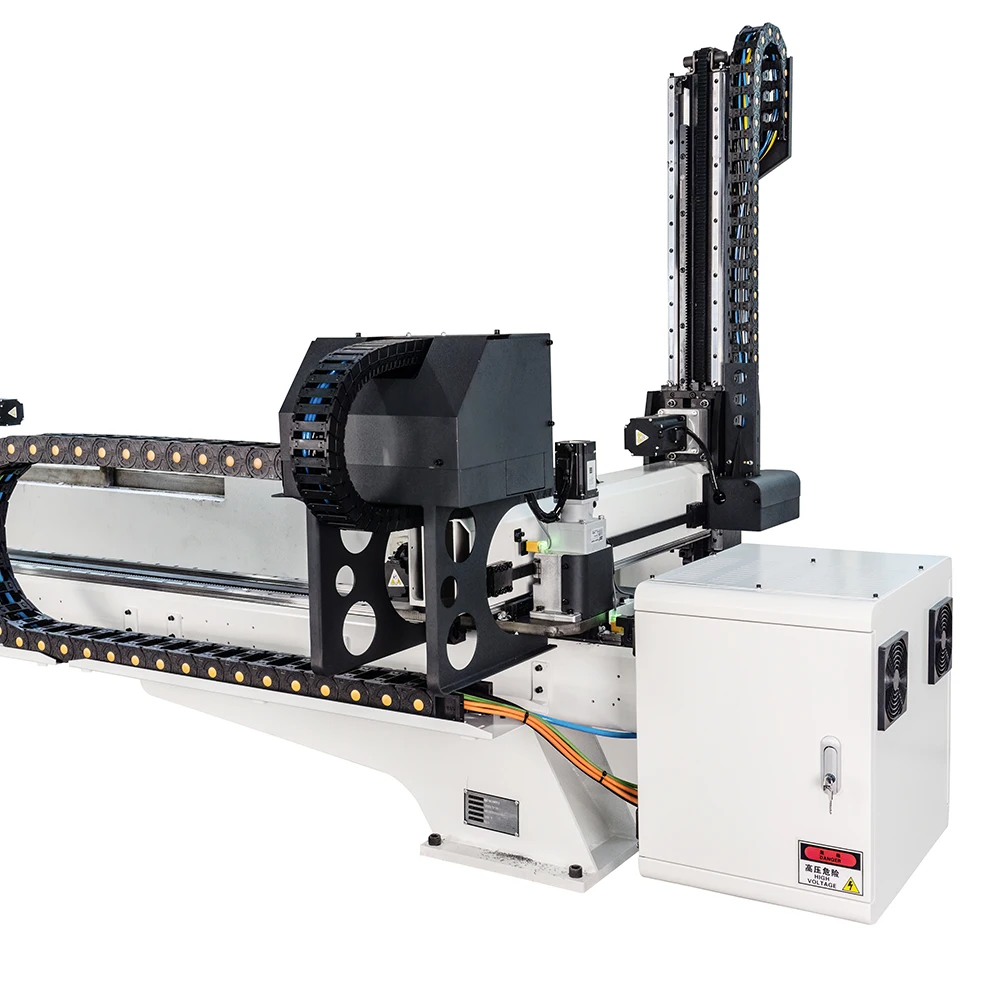

We carry full servo range of 3 and 5 top entry robots axes 3 and 5, sprue pickers, and 6-axis Fanuc. Our team can create entire automation unit includes customized jointed arm robot equipment, as well the end of arm-tooling.

Guangdong Heeexii Robot Technology Co. Ltd. founded in 2019 and is top-notch company that concentrates on R and D manufacturing as well as the sale industrial robots. The company has many employees who have ten years' jointed arm robot.

Heeexii's main values the pursuit of excellence as well as the desire be persistent. They also include creativity and a growing attitude excellence above oneself professionalism through determination, and the highest quality due professionalism. Heeexii Robot adheres to ideals of quality first and continual advancement. It offers solid reliable users while {{keyword} to China's smart manufacturing.

The company's products used jointed arm robot of industries including computer peripherals, home appliances optoelectronics cosmetic packaging, automobiles their parts, metal processing parts, precision gear industry, PET preform industry, household necessities, mobile communication industry, medical supplies packaging industry.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. All Rights Reserved