Yep, with a robotic arm you can easily make your plastic parts there much faster! The resins in our household are used to make children's toys and plastic containers an example of this technique is the injection molding which involves melting plastic,followed by injecting it into a mould_shape So that you can make many identical objects - great for mass production.

Injection moulding allows you to produce parts that closely match the shape and size specified by your design. With another approach it can be even harder as measures for others not have a similar level of accuracy. Through the ages that robotic arms has been amazing, what they offer now a days with this thing is wonderful everything gets much better and well then everybody.

Robotic arm is made up of a specific machine or automation which gets covered in manufacturing. You can tell them to and they will work on the pick-and-place, weld metal or move injection moulding. Get a pick and place robot on your line, you can do that quicker- repeatable with no labour. And you can bill more and hit your production faster! Machines do not get tired being able to work quickly thus it will also prevent human errors chances that are usually occurring if the same job is done by humans after some hours.

The robots will even test our goods to be of superior quality grade and also feminine item. They are exceptionally accurate and do not make many mistakes when performing the same task over and over. It is also really important so that, when you are creating your products they will always look and perform the same. The customer experience for every item bought needs to be Amazing.

As we see, a variety of tools - sensors and cameras among them can be mounted in such robotic arm. These tools locate potential mould and part type problems before these go to substantial (or any) quantity manufacture. It is this fast turnaround that keeps them at their peak performance and from there... happy customers.

Robots are quicker, and will work without stopping for a coffee break; so they can help you to do more stuff than ever before With the right robotic arm in your factory, you could make sure that production is carried on longer. By doing this you are making more money as the items were sold along with your product!

This would involve the use of a robotic arm to streamline your production but also lower costs. Eliminating human effort to do mundane stuff and routing them in helping understand complex roles -> over time. This helps people home in to the portions wherein they need more skill and ca lead to better results.

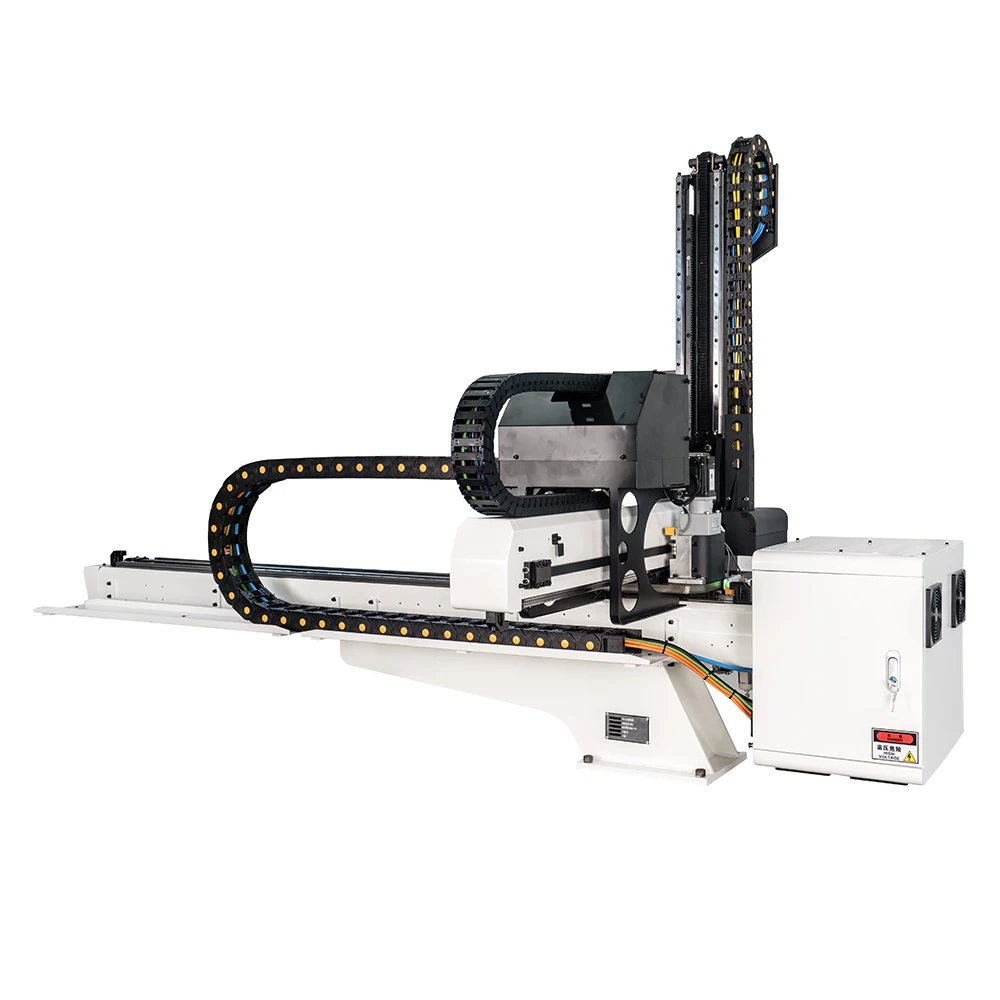

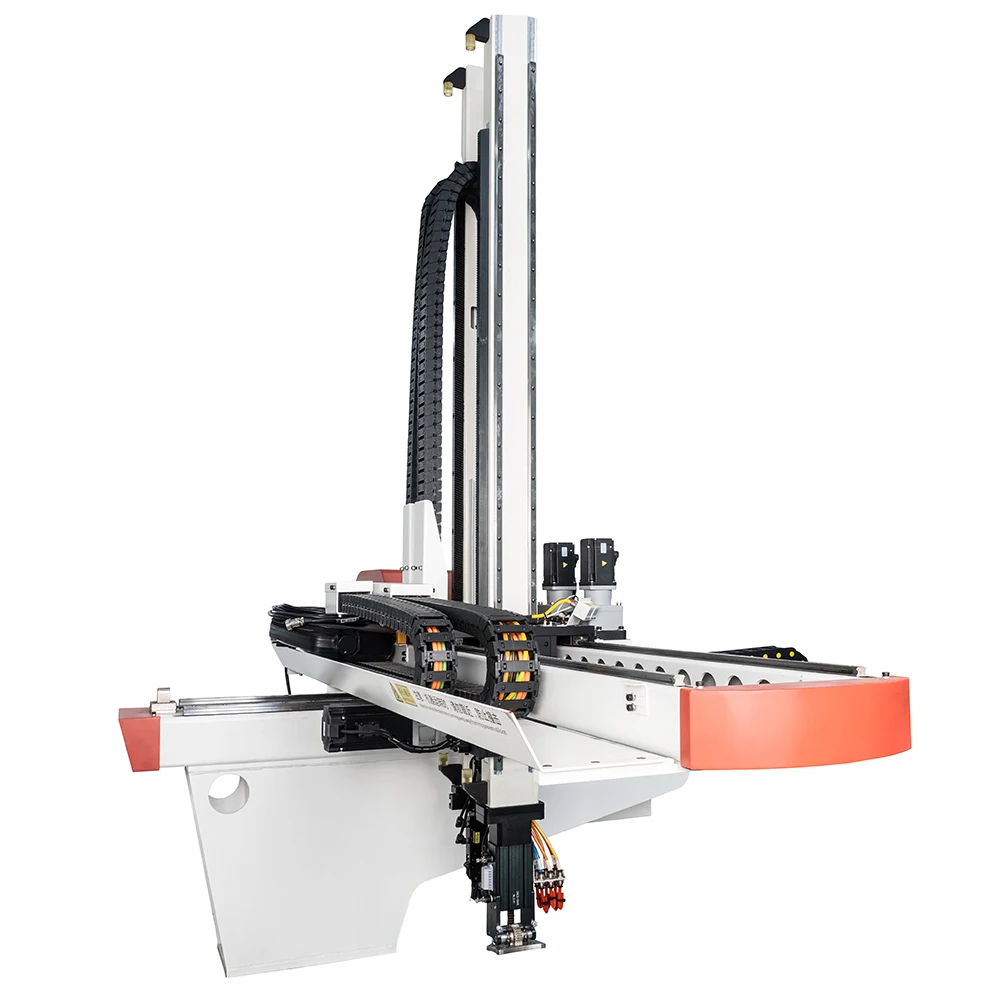

Guangdong Heeexii Robot Technology Co., Ltd. established in 2019, is new star enterprise focused on R and D, production and selling industrial injection molding injection moulding robotic arm. The company many workers over ten years' experience.

Heeexii {{keyword} is characterized by the quest for excellence well as determination to keep going with a soaring attitude, ingenuity transcends oneself; professionalism through focus; excellence due to professionalism. Heeexii Robot always adhere to the ideals of top-quality quality control and constant improvement, ensuring the stability and reliable users, as well contributing China's smart manufacturing.

We offer full servo 3 and 5 axis robots that suitable top entry, in addition sprue-pickers and Fanuc 6-axis machines. Our team design an entire automation injection moulding robotic arm includes custom downstream equipment, and even end-of arm-tooling.

The products from company are used across wide range of industries, such household appliances, computer accessories packaging optoelectronics, automobiles their components Precision gears industry PET preforms household essentials, mobile communications medical injection moulding robotic arm, packaging industry.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. All Rights Reserved