The new is an injection molding robot automation that will change the way plastics are made as well, prefectly tailored for the production of plastic items and parts this technology makes everything faster and easier. This state of the art procedure involves robots doing what a person does in an assembly hall. Read on to learn more about the different advantages of injection molding robot automation.

Speeding up production rates is one of the main reasons why injection molding robot automation software scores so high. Manufacturers are able to produce more plastic parts at a faster pace by taking advantage of the swift ability from robots. This greater efficiency also means that factories are able to keep up with their production around the growing demand for it, enabling them in turn expand their market influence.

Also, it reduces the errors in injection molding process by using robot automation. Robots, unlike humans who can feel fatigued or distracted, are able to perform tasks with unrivaled precision and regularity. Therefore, the plastic parts that are produced come out uniform which is why the consistency in form and size promotes high quality results.

Goods that effortlessly carry on through the assembly line by way of customized devices configured specifically for materials handling or injection molding robot automation only serve to hasten down production. They are intricately coded to carry out repeatable, specific functions far more productively than a human operator ever could. The process not only fetches factories a higher number of processed plastic items but also saves on the depleting resource volume, time and capital.

In addition, Injection molding Robot automation can lift the level of performance on a production line. Robots specifically are able to take on tasks beyond the human limit, thus aiding in creating more complex and highly detailed design elements. This sophisticated technology enables factories to supply high-quality plastic articles with exclusive characteristics and fine workmanship.

This continuous operation capability of robots enables manufacturing activities to run efficiently and productively. Robots, too, can generate high production with respect to human labor - they are able work without breaks. This basically allows factories to reach production targets much quicker launching plenty of plastic items with cut down time wastages.

Injection molding robot automation has transformed the industry and undeniably makes one of its most significant impacts. This technology is changing the faced created by manufacturing, it drastically automates and hastens production to maintain consistency. This results in faster production of high-quality plastic items, enhancing profitability and operational success.

Heeexii Robot is characterized by the desire excellence as well as the determination keep going as well as the ability innovate, and a growing attitude; excellence transcending oneself; professionalism because focus; and excellence due to professionalism. Heeexii Robot will always adhere the spirit of first-class quality control and constant advancement and will {{keyword} stable and reliable service users as well as contributing to China's manufacturing industry.

Guangdong Heeexii Robot Technology Co., Ltd. established the year 2019, is a new star enterprise focusing on R and D, manufacturing, and sales industrial injection molding robots. The company has dozens of employees ten years' experience in the injection molding robot automation.

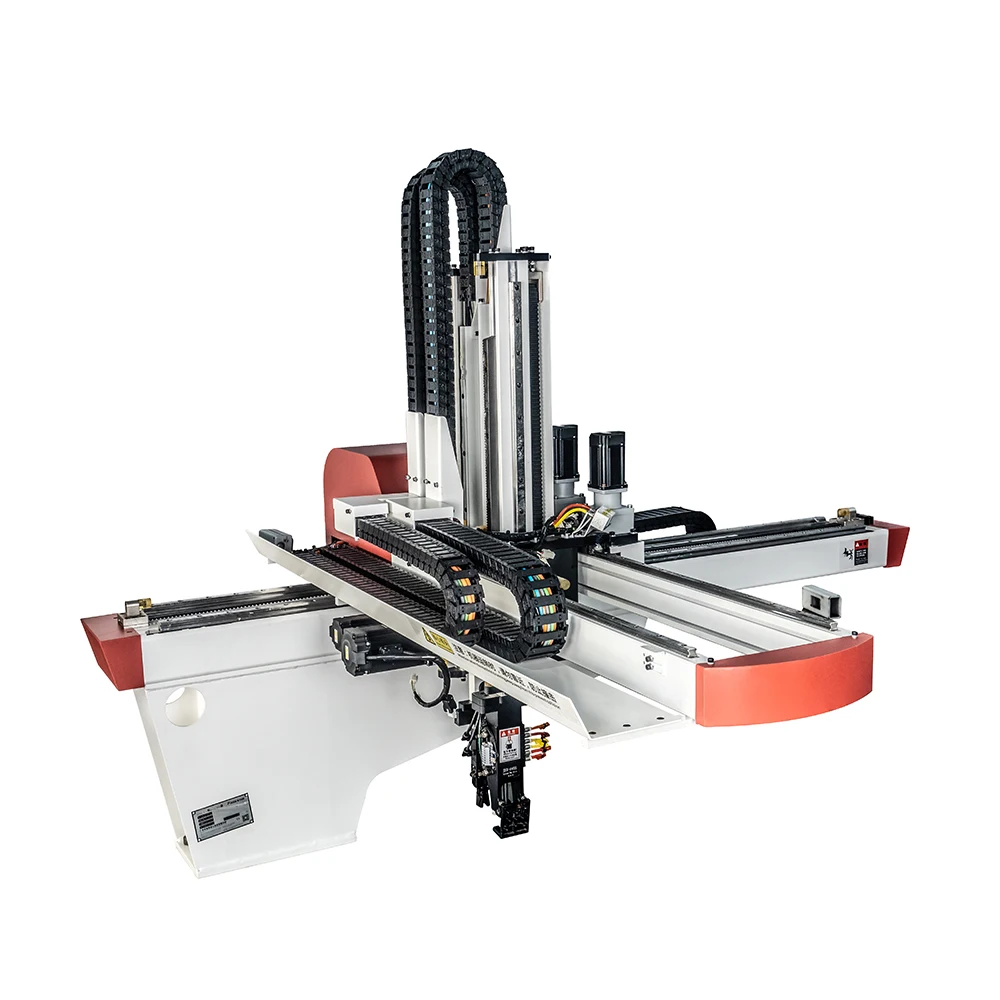

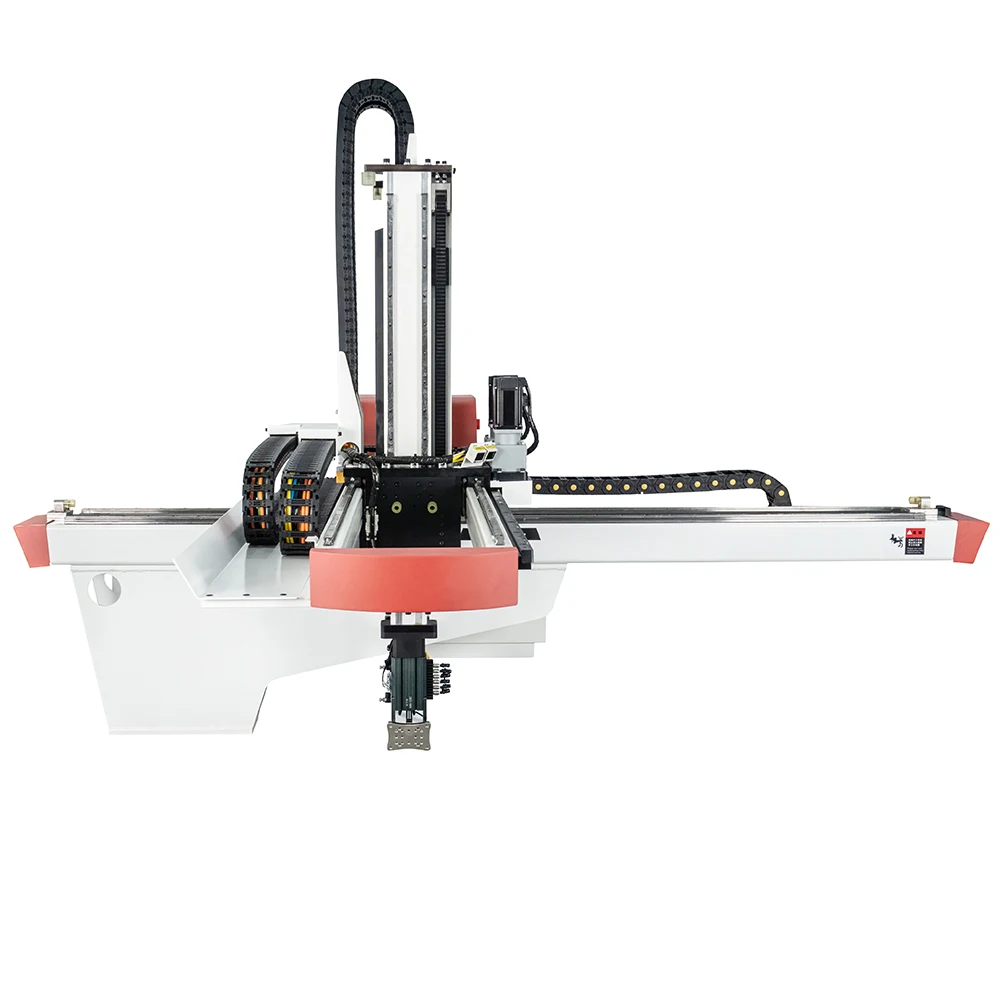

We offer servo servo full 3 5 axis machines for top entry as well sprue-pickers and Fanuc machines six axes. Our team will injection molding robot automation automation system is complete, including end-of-arm-tooling and custom downstream equipment and types of equipment molders could use. The main technology R and D team follows the independent research and development process and has secured a variety of intellectual property rights and patents.

The products the company used across wide range of industries, such computers, home appliances packaging for optoelectronics, automobiles their components, precision gears industry, PET preforms industry home essentials, mobile communications medical equipment packaging injection molding robot automation.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. All Rights Reserved