Industry Applications & Outcomes of Axis Robotic Arms

However, another thing in the new era we saw are these Axis robotic arms that changes production astronomically. These are the devices that represent a sea change in terms of precision, adaptability and throughput for manufacturing. Used across industries for automating manufacturing and related processes, streamline production processes to lower cost.

Key Insights Of Axis Robotic Arms in Industrial Sectors

In simpler terms, two-axis robotic arms are optimal for the most basic and manual labor tasks industries demand. Complex moves are more precise and a minimum wasted move in terms of work produced due to the ability to go almost any direction. These are Omega-designed right arm, perfectly suitable for pick & place and welding etc. which is mostly completed in multiple cycle with precision part individually processed at each step supported by optimal production environment like continuous stable operation having very less down time thereby contribute high throughput of quality parts.

One of the key areas that really distinguish axis robotic arms it their potential (not all do this but good ones are very capable at it) capability to work along side humans what is referred to a cobots doing human tasks. This way, many safe-to-insert operations can be executed that go on to free u humans up for non-robotic work (value added higher order tasks) leaving the boring or dirty/hazardous jobs for their digitised counterparts. The training is such that these robotic arms, stimulated with advanced sensors and AIs algorithms can self-learn at every task they perform to prove their efficiency over time. This pipeline of adaptive learning leads to shorter cycle times, higher throughput and a dramatic increase in productivity across countless disciplines.

Some day, robotic arms with axis designed for assembly line manufacturing will be built just like Forax 3D. Powered with the machine learning and communicating through IoT, these robotic arms are being intelligent enough to take independent decisions. They will also be smarter, detecting any problems before they actually cause a breakdown and self-diagnose issues ahead of time so when maintenance is needed it's not just the more-reliable vehicle but that fleets no longer have to worry about downtime-no surprise waiting for - because as these newer trucks are almost semi-running on auto-pilot in some incidents. Where flexibility of product lines needed to be transitioned has driven even faster advancement in flexible manufacturing systems, and these need to meet the higher expectations now spawned from being served by a consumer-based market for 'on-demand' highly customized products - still at cost but without compromising on rapid deployment nor total scalability. Only in being an innovation engine for manufacturing as a whole, with respect to the data-driven and market trends that production lines are churning out.

Axis robotic arms are widely employed due to this flexibility in many industries, including automobile manufacturing, electronics assembly, food processing and pharmaceutical production. Robot arms can be fitted with end effectors and software passes appropriate for each sector mangiraikanieres are used. With this solution, the robot can efficiently do even a very delicate job as well regular tasking on scale in 6-DoF (six degrees of freedom; Shikumi Nabiki). For businesses, they can purchase cherry pick robots for a small investment and be advised to do so when as their business expands; conveyor belt robot arms are still the best option that will likely remain relevant well in tow by most of these future technological changes if properly connected.

AXIS ROBOTIC ARM BASIC FUNCTIONS- At it the most basic level a robotic arm automate heavy lift for repetitive manual task we do in industries or any work field you can be thing of. This results in them having a much lower error rate compared to human operators and therefore, they can perform tasks at high speeds. Being built-in straight into the assembly line, as part of that same automated system, these robotic arms perform tasks such us welding or painting, either for packaging components; they make sure every unit produced has the exact quality characterizers resulting in better and somewhat continuous flow. Further, 24-hour working is also one of the sources to increase labour productivity as industries can meet higher demands made on them and without affecting the good quality.

Increasing Productivity with Axis Robot Arm

One of the key reasons in driving up popularity is its exceptional application use among shared cobot environments; which seems to be a common selling proposition for collaborative robots. Put simply, this distribution of labor bolsters security but also allows human staff to focus on better nuanced tasks as the robots fulfill any monotonous or hazardous responsibilities. These robotic arms also come integrated with a variety of sensors and AI, which makes them to quickly learn anything new that they will work on in real-time - making their next one faster (reduced cycle time) for the better overall efficiency. As a result, industries are highly productive and adaptive in the face of market forces which now gives them an advantage.

The Wave of Automated Trio is Reforming the Future in Manufacturing Industry

The degrees of freedom Axis robotic arms can be used on those new fully automated production lines is high as a kite in terms of innovation. These robotic arms can predictively with the help of new generation technology identify potential issues that may rise and all together take autonomic action within defined boundaries. It has also unlocked the development of flexible manufacturing systems which can quickly retool lines to new demand patterns, meeting growing market desire for bespoke goods without penalty in either speed or cost. Which also brings production line assembly robot one step closer to the real-time data informing which products it puts together and possibly could reconfigure how components are approached, much like they do for certain models at mass-production car plants.

The products of company employed across a wide range industry, such as home axis robotic arm, computer accessories optoelectronics packaging. Automotives and components, precision gears industry, PET preforms industry home essentials, mobile communications, medical supplies packaging industry.

Heeexii Robot is characterized by the pursuit excellence well as the determination to keep going well as the ability to innovate, and a growing {{keyword} and a desire to excel beyond oneself. professionalism through focus; excellence because professionalism. Heeexii Robot will always adhere to the spirit of first-class quality control constant growth, offering stable and reliable users, while making contributions China's innovative manufacturing.

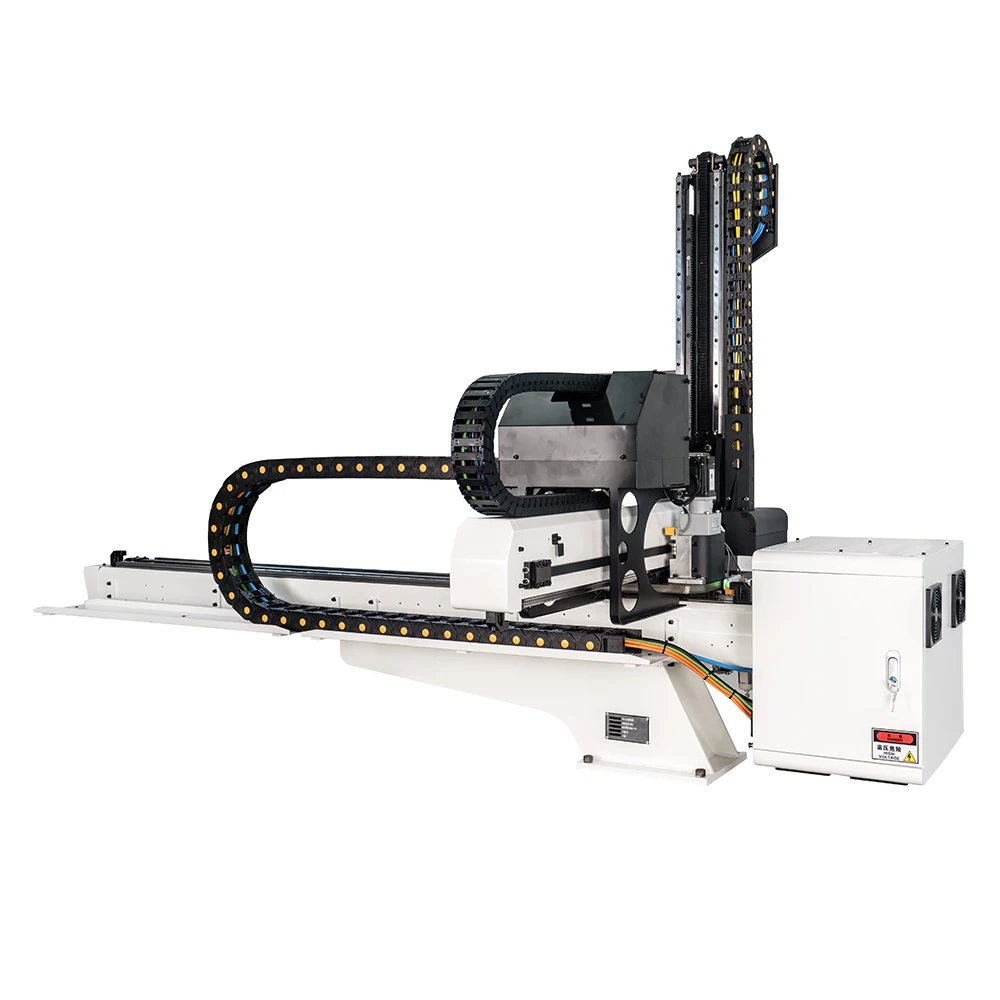

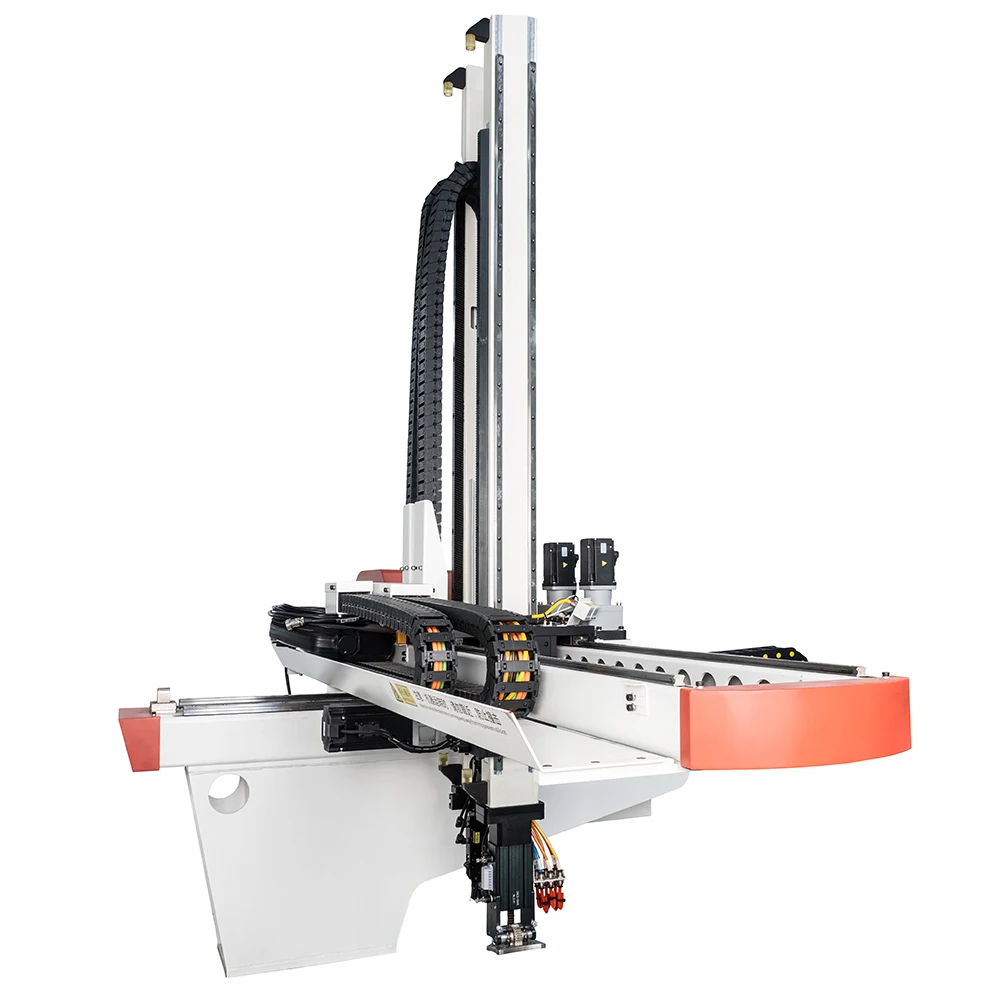

We offer complete servo 3 5 top entry robots with axis robotic arm as well as sprue pickers and 6-axis Fanuc. Our team develop an entire automation cell comprising end-of-arm-tooling, customized downstream equipment, and different equipment molders use. The primary technology R and D team is committed the independently run research and development process and has accumulated a range of patents intellectual property rights.

Guangdong Heeexii Robot Technology Co. Ltd. was established in 2019 and a top-notch company that concentrates on R and D and manufacturing as well as sales axis robotic arm robots. The company a staff of employees more than 10 years' experience in industry.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. All Rights Reserved